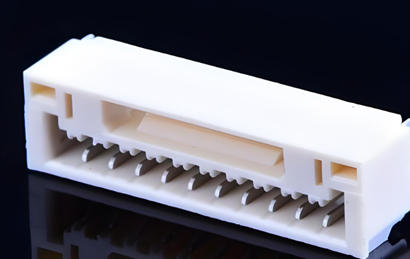

Wiring harnesses are essential in modern electrical systems, ensuring proper power distribution, signal transmission, and system functionality. However, like any complex assembly, they can face issues over time due to environmental factors, mechanical stress, or manufacturing defects. Identifying and resolving these problems is critical to maintaining the reliability of any device or system they support.

In this article, we explore how to troubleshoot the most common issues in wiring harnesses and how FPIC’s quality assurance and advanced testing practices help mitigate them before they reach the customer.

Rayconn Commitment to Wiring Harness Quality

Rayconn, we take reliability seriously. Our wiring harnesses are tested under strict standards before leaving the production floor. We support global compliance and carry certifications such as ISO 9001, ISO 14001, ISO 13485, UL, TUV, and IATF 16949, ensuring our products meet industrial, medical, and automotive application requirements.

We also implement:

VDA 19.1 cleanroom standards for high-purity applications.

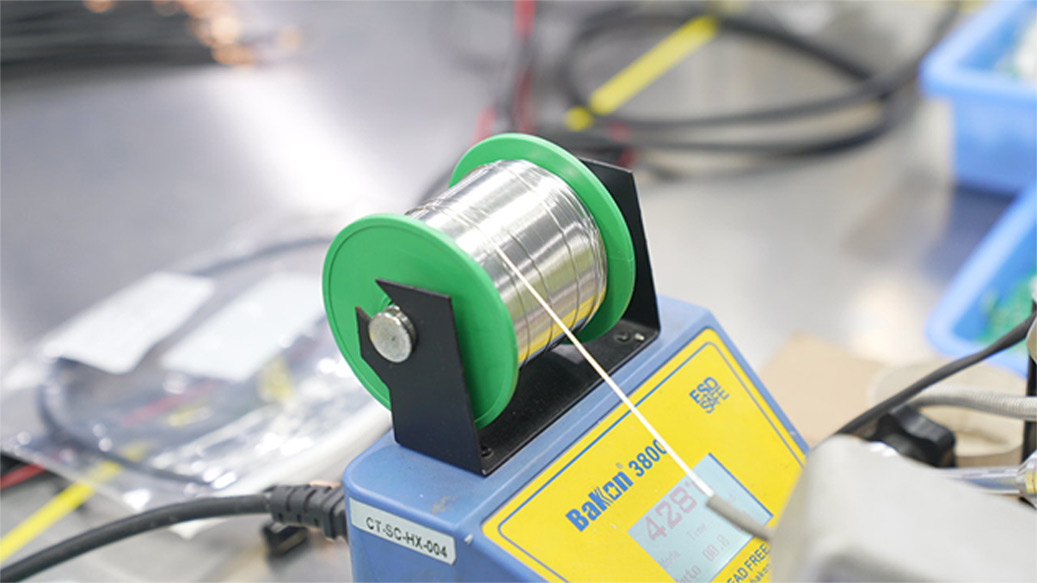

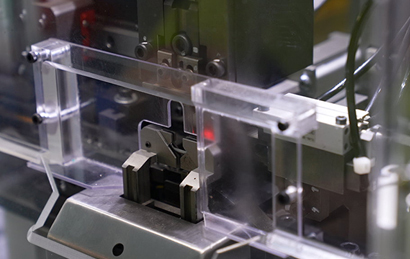

Automated testing for continuity, shorts, and pin mapping.

Material traceability and lifecycle monitoring.